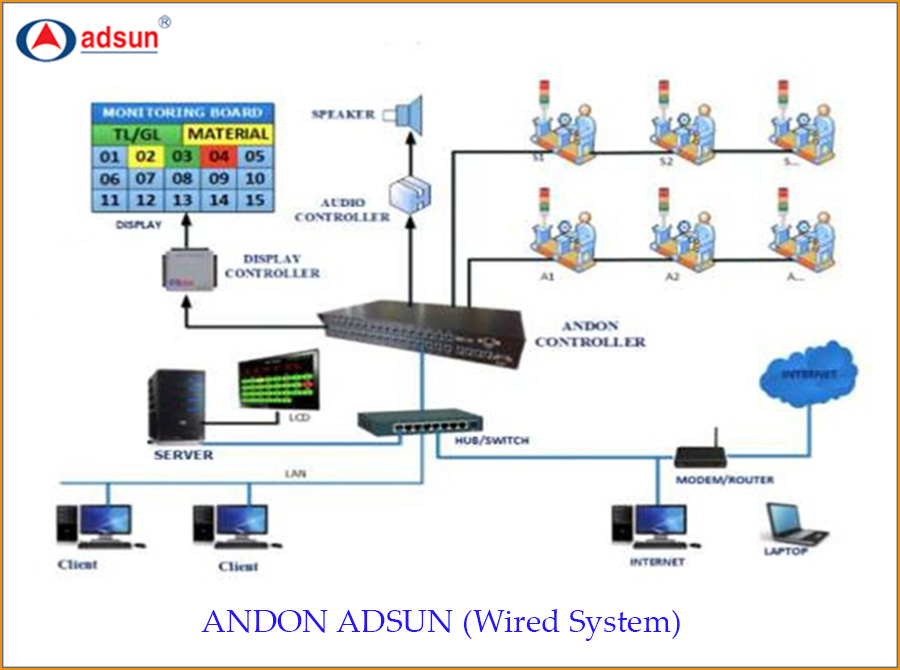

2. ANDON ADSUN System Wired

In order to meet the increasing demand in the Vietnamese market, mainly in manufacturing factories and industrial parks throughout the country.

-

Anh Duong Electronics and Telecommunications Joint Stock Company (ADSUN JSC) we would like to introduce a production management support system of ANDON ADSUN SYSTEM, which is researched and produced by our company.

-

This system is designed to control the details of events at each critical stage in the production process.

-

The system helps managers control production processes and troubleshooting better and faster with the highest reliability.

MODEL GENERAL SYSTEM ANDON ADSUN AND WIRELESS SYSTEM

The production management system ANDON ADSUN is defined as a system that helps support production management to achieve the best performance in the production management of the enterprise. With the following functions:

-

Immediately report incidents by a system of signs and sounds.

-

Notice of requirements for material supply (material code, color) according to each shift.

-

“1-touch” quick-call workers: maintenance, line management, other emergency incidents, …

-

Warning of operating device parameters: overheating, emergency stop, …

-

Monitor real-time working of machinery, time of machine breakdown due to damage, maintenance time, frequency of broken machines, manage records of machines and equipment on convenient software (use App phone and QR Code for device management).

- Online monitoring, quick reporting of technical time for processing machinery for production.

-

Production productivity report: product taget by quarter / week / day and actual output achieved compared to taget.

-

Keep track of all activities through Website & Mobile App, software decentralized according to functions and tasks of each department.

-

Especially the scalability of the system: because we directly research and produce, the system has the ability to expand the features according to the specific management requirements of each factory, with fast response time, effective fruit.

-

Pre-designed data connection ports used to interact with sending / receiving data with the ERP software system of factories.

-

The ability to connect and expand the centralized management system for factories (data management of the company).

-

Designed according to each individual management needs of each customer.

Components in the system

Product features:

Product features:

This is the device to receive signals from the central controller and display information on the system of terminal signs: table lamps, LCD TVs (HDMI ports), computers …

Detail ...

Product features:

Communicate with the central controller AD-W- 512 via RS485 port.

- Operation principle: When there is a signal activation from the working position (Sub) the information will be transferred to the central processing device (AD-W-512) and the signal will be transmitted to the control device. sound control. Depending on the event triggered – the corresponding sound will be emitted to the speaker of the working position.

-

There are 8 music output ports corresponding to 8 separate lines (each with a separate speaker). If at the same time more events are triggered – the system will play sound according to the queue principle (each time the music plays only 1 line after 20 seconds after another pass).

- There are 02 ports to broadcast general events when needing to notify the whole system.

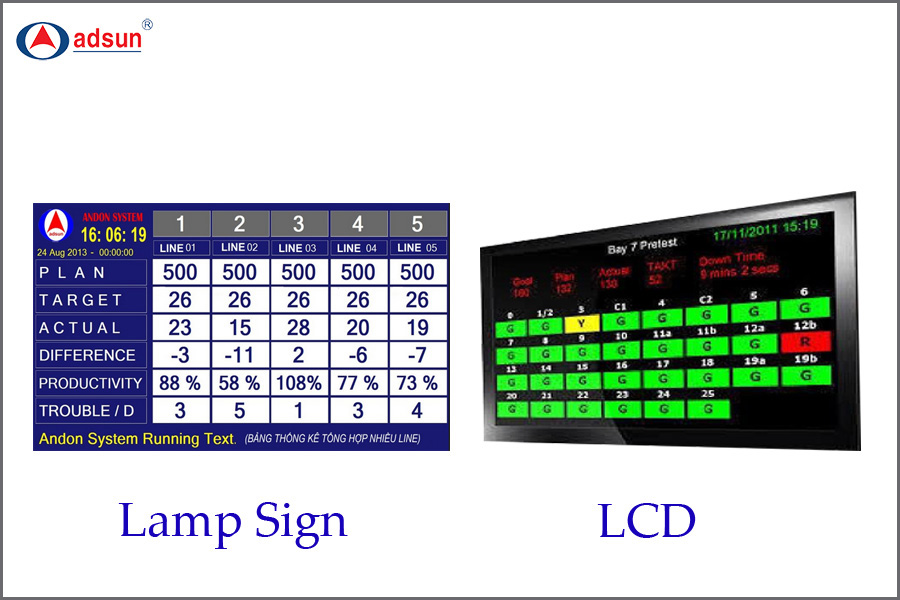

Product features:

A device that displays information in the system, production process status information. Depending on the requirements of customers, the display information can be used: table light (lower cost), television screen (via HDMI port), computer screen …

Detail ...

Product features:

As a terminal in the system – arranged in the working position of workers so that everyone can activate notifications about: supplies, techniques, maintenance … signals will be transmitted central processor.

Product features:

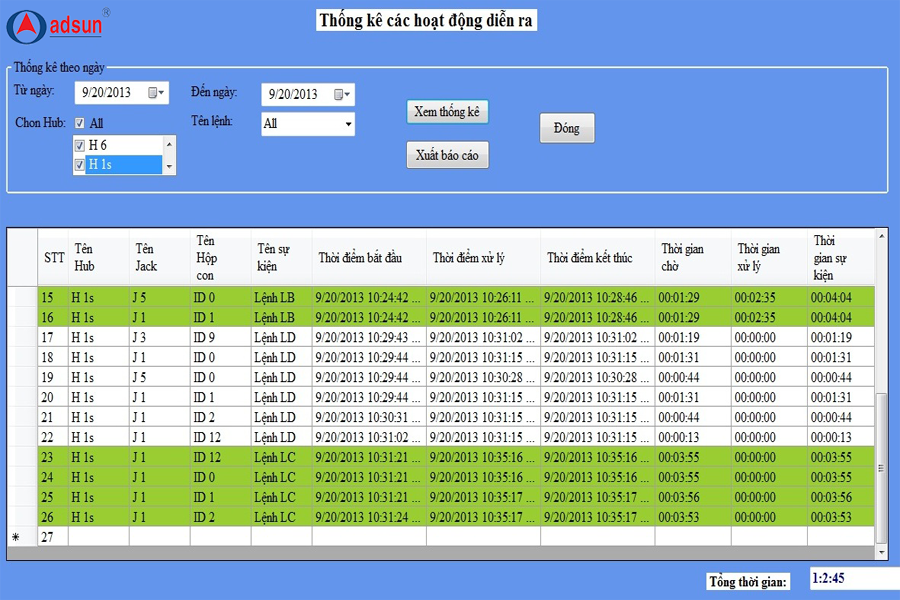

- Displays ongoing events on the admin screen over time.

- Full statistics of events taking place by day – month – year, according to each central controller, each group, each child box (Option according to user preferences).

- Data of all events taking place throughout the system can be exported to Excel file.

- Manage via local network (LAN) and over the Internet.

Tiếng Việt

Tiếng Việt